Historically, the company started out by supplying machines designed to meet the needs of local wine producers.

This traditional approach was still far from current industrial processes, even if initially it was responding to clear on-going needs.

Then things really started to change…

In 2006, COSTRAL decided to manage all its business expertise internally to design and manufacture its range of bottling lines.

Today, up to 97% of the components used to assemble our machines are manufactured in our workshops.

This decision has given us greater control over our costs, lead times and above all, the quality of each piece of equipment we deliver.

Research & Development, prototype design and innovation

Since 1975, COSTRAL has been allocating a large part of its turnover to Research & Development in order to develop new processes and constantly enhance our range of bottling lines and existing machinery.

A team of engineers supported by a team dedicated exclusively to prototype production are both constantly working on future bottling equipment designs.

To adapt to technological developments, their skills are increasingly broadening to include IT, robotics as well as artificial intelligence.

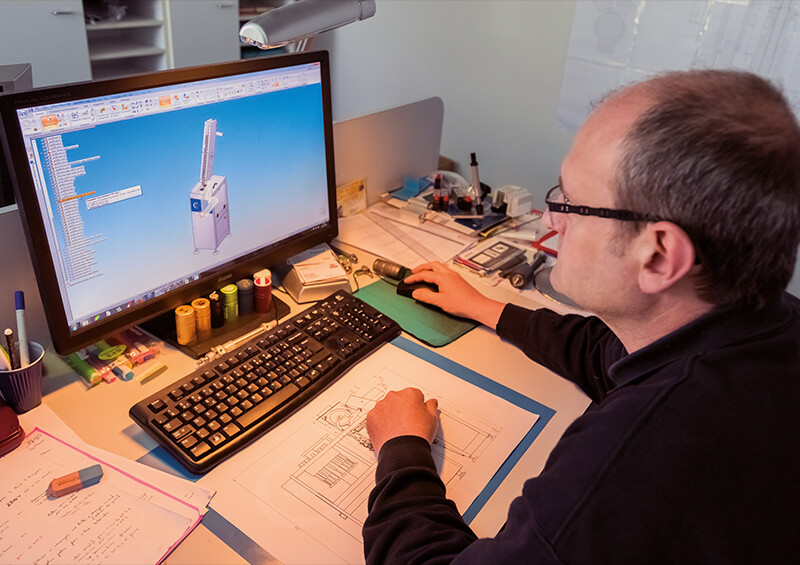

Design office and special bottling methods

Our design office/testing office take care of the entire design of our machines and equipment, from 3D modelling and assembly of each part, right up to producing manufacturing plans for the workshop.

In fact, the design office is the central source of data, providing expanded views and parts lists enabling traceability and After-Sales service requests to be processed quickly.

It also takes care of the design and production of non-standard parts (connection between 2 pieces of equipment, supports for new corks or caps, etc.) allowing us to respond to all of our customers' requests, even those we hadn't

thought of!

The COSTRAL design office is also involved in designing site plans.

These can be site plans aimed at optimising the integration of a new bottling line.

As an example this could include a cellar installation, considering all space dimensions as well as any other constraints (pillars required, differing levels, etc.). It is also an opportunity to plan for the integration of a new machine into an existing

assembly.

Likewise it may be a layout for a bottling system in a truck to create a mobile bottling line.

Automation, electronics, IT, pneumatics

A wealth of skills are required to develop and manufacture the equipment involved in a bottling line.

COSTRAL offers in-house expertise covering automation, electrics/electronics, IT and pneumatics.

We believe that internal control of these different areas is key for our development and for the quality of each piece of equipment that leaves our workshops.

However, we also know how to surround ourselves with specific skills to help us learn about new technologies and increase our knowledge.

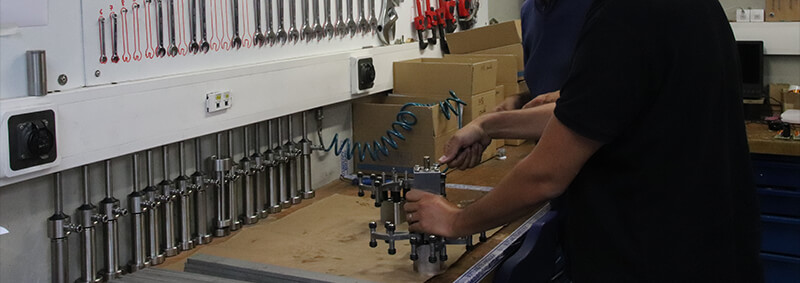

Manufacturing (sheet metal work, machining, etc.)

Manufacturing and assembly of our bottling machines is all carried out in our factory, based in Riquewihr in Alsace. This decision gives us total control over our production processes and lead times.

Most importantly, this enables us to control the quality of each component used in manufacturing our machines, from start to finish.

To do this, we have a sheet metal division, primarily working with stainless steel (including welding) and a machining division (milling/turning on 5-axis CNC machining centres).

COSTRAL is by your side every step of the way

Your project from start to finish

Are you looking for a new bottling line, need additional equipment or an upgrade?

Whatever your project, COSTRAL is here to help you make it happen!

Global quality control

At COSTRAL, our Quality division gets involved at all levels.

Their experience is used for developing new machines which take into account any feedback relating to machines already in operation.

It also takes care of quality control for all our machines' components prior to leaving our factory in Riquewihr.

In addition, each machine and each piece of equipment designed by COSTRAL has its own preventive maintenance plan. This information is the result of capitalising on the knowledge and experience of our quality division.