You may not know, but we are the key partner for VINOLOK, the world leader in glass stoppers!

COSTRAL places more than half of the VINOLOK caps on the world market.

This is why we offer you its new generation of capping solutions to develop your brands and your design.

Two capping solutions available according to your needs

Vinolok capping is carried out in three stages: Sparging, positioning the cork in the bottle and inserting the VINOLOK stopper securely.

In addition to proven technical performance, VINOLOK offers adaptability thanks to two capping solutions , one of which is necessarily made for you!

A VINOLOK Kit ready to fit to your machine

Do you want to complete your bottling line by adding a high-performance capping solution?

The Vinolok kit adapts to your existing equipment so that you can benefit from the performance of VINOLOK corking in all situations.

Easy and quick to install, this "ready to use" VINOLOK Kit allows you to improve your bottling equipment, by introducing a capping solution recognized internationally for its quality.

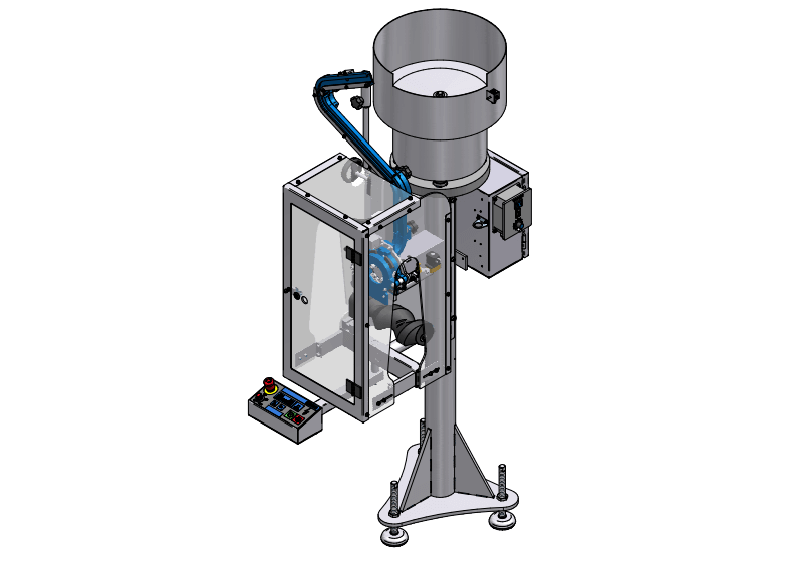

A stand-alone capping machine for VINOLOK stoppers

Do you need a separate stand-alone dispenser for your glass top capping system (High Tip or Low Top)?

With the VINOLOK capper, you have a stand-alone machine that enables you to complete your glass product bottling.

The result is a comprehensive bottling line with automated management of the entire capping process in perfect harmony with your complete bottling line.

Features designed to optimize corking processes on your bottling line

VINOLOK solutions have all the characteristics necessary to stop your bottles at the desired run rate and to get the best performance out of your bottling line:

- a stainless-steel foot placed on the ground and to be fixed against an existing conveyor, supporting the dispenser and the removal head,

- an automated vibrating dispenser with stainless-steel selection hopper (D: 500 x H: 250mm) specially coated to prevent glass breakage,

- a motorised Archimedes' screw for selecting and centring bottles

- an aluminium downpipe, with hinge allowing automatic compensation of differences in bottle heights, and cap presence detector,

- a device for timed injection of neutral gas into the necks of the bottles before they are capped,

- a rotary head with five positions, driven by Brushless motorization, ensuring the removal and insertion on the fly of the plugs,

- an encoder (to be installed on the existing conveyor motor) for synchronisation of the dispensing head with the speed of passage of the bottles,

- protection by a polycarbonate cover,

- an electrical box with low voltage controls.

COSTRAL Services: By your side

Our COSTRAL Services division is by your side throughout your project, right up to installation, providing training for your operators.

Every machine is supplied with a general maintenance guide.

We provide a specially dedicated free hotline offering After-Sales support to handle any queries concerning the functionality of your COSTRAL machine.

Contact us directly on +33 (0)3 89 47 89 45.