All of COSTRAL's expertise offered to juice producers

With its extensive experience in developing and marketing bottling lines (and mobile lines) for wine, COSTRAL also offers high-performance bottling solutions dedicated to juice products.

As the juice market is currently a booming industry, juice bottling equipment represents a significant part of our product portfolio.

Our juice bottling solutions are founded on innovative technologies, developed in-house and under constant review for enhancement. This is the essence of our brand's reputation.

By choosing our equipment to bottle your juices, you are investing in a system that is efficient, reliable and scalable over time.

Developing technologies used for your future equipment also allows us to adapt our solutions to your specifications, achieving a juice bottling line with no compromise.

Bottling solutions

Special features to consider for juice bottling lines

Bottling lines made for juice products

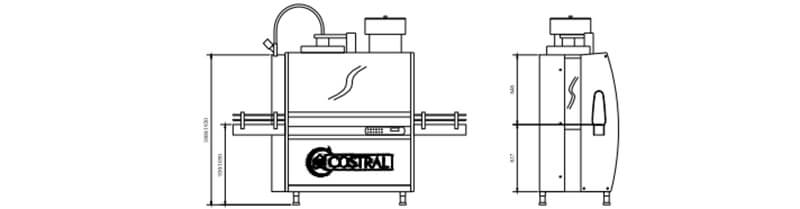

Based on your requirements, our juice bottling solutions can handle the whole process, from empty bottle to boxed product, ready for shipment. At each stage of bottling, we provide a high-performing and proven solution.

We know exactly how to handle each part of the process, from rinsing/sterilising, filling and levelling, as well as corking, crown capping and screw capping.

The rinsing process has been the subject of numerous research studies which have enabled us to offer up to 4 different rinsing injections with air, inert gas, pure water or steam, and water containing a sterilising solution or peracetic acid solution, ensuring your bottles are entirely sterilised prior to bottling.

When it comes to filling, we know exactly how to bottle juices requiring a hot filling process, such as apple juice or other thicker juice. To do this, we have developed special juice nozzles equipped with specific seals, capable of handling this type of sensitive product. At the same time, we can advise you on the type of pump to use depending on the vacuum required during bottling.

When it comes to corking/capping, there are many different types of caps in existence (crown caps, screw caps, etc.). Also, depending on the type of capping selected, we can either offer you an existing solution or carry out a complete review of what is required to handle your bottling and capping processes. Each Costral machine is managed by our technical team, on a case-by-case basis, as your issues are our issues.

Cleaning and sanitising your bottling line

All our machines are designed entirely in stainless steel, making sterilising, cleaning and maintenance, simple and highly efficient.

Our filling nozzles for juice can easily be detached for daily cleaning after each bottling production run.

Your juice bottling project

Having a good design is half the project completed!

Every day, our teams (including ourdesign office and technicians) advise our customers in selecting and implementing their future bottling equipment.

It goes without saying that we have already handled a vast number of questions and technical challenges, and we never fail to find a solution.

We share our experience and expertise with you to help develop your project right from the start, by providing effective long-lasting bottling solutions to meet all your needs and special requirements.

Bottling solutions specially designed for juice products

We have a Research and Development department, with in-house prototype designers, entirely focused on product innovation and constantly looking for new solutions and enhancements.

Some liquids like juice require special processes when bottled and our equipment is designed to handle these requirements.

This was the case, for one of our customers who produces craft juices in Austria, for whom we developed a “special juice” filling nozzle. The filling nozzle was developed to bottle hot, greasy and sticky products. It can handle particularly high temperatures which are necessary for certain types of bottling, in particular, apple juice.

COSTRAL is by your side every step of the way

Your project from start to finish

Are you looking for a new bottling line, need additional equipment or an upgrade?

Whatever your project, COSTRAL is here to help you make it happen!

COSTRAL Services: Always at your service and here to help when you need us

Always there, by your side

COSTRAL has a quick-to-respond COSTRAL Services division dedicated to handling all technical support interventions in the field.

We continue to support you on site from installing your new juice bottling line to providing your operators with comprehensive training.

We provide local After-Sales support with a free hotline that can resolve up to 80% of technical questions and concerns over the phone.

Our team of technicians is on hand to offer you quick assistance in your local area.

Making it simple for you to operate your juice bottling line

To make your life simpler when operating your new bottling line, we supply user manuals which include helpful tips on cleaning.

We also provide videos to assist you with dismantling/reassembling parts and tutorials on cleaning procedures to ensure your production line runs smoothly.