At COSTRAL, we have a team of highly-experienced project managers and designers who have the best working environment and all the necessary tools and time required, to ensure your project is a success.

It is precisely this working environment that explains our ability to constantly innovate, providing such high-performing bottling solutions and in doing so, safeguarding your investment.

Our specialists are here to share their expertise and experience with you, to develop your project and provide an optimal bottling solution, from all perspectives.

What's more, our products already in service, also benefit from new developments.

We are constantly working on continual improvements for the equipment integrated into our machines, even the most standard models.

Our development always has one key objective in mind: to improve the quality of our products by offering our customers the very latest technology in the bottling industry.

Inerting and oxygen management in bottling: movable nozzles

Oxygen, a key topic for many wine producers and brewers, is a difficult variable to manage in the bottling process.

A few years ago, we developed inerting using longer spouts inserted into bottles by several centimetres, prior to filling. In order to optimise this inerting phase, testing was carried out at the AGROSCOPE oenological research institute in Changins (Switzerland).

Conditions: Run rate = 2,000 bottles/hour; Operating injection pressure = 2 bars; nitrogen injection time = 1s48 Injection of nitrogen once the nozzle is in the top position and injection shuts off prior to leaving the bottle.

Results: 0.3% of oxygen remaining, i.e. the elimination of 99% of the oxygen present in the bottle before inerting (for information, there is 21% of oxygen present in the air).

In conclusion, unlike our competitors, there is no need to empty the bottle in order to achieve excellent inerting results.

NB : The 0.3% of oxygen remaining is mainly due to the purity of 99.5% of the nitrogen injected.

How our filling valves differ

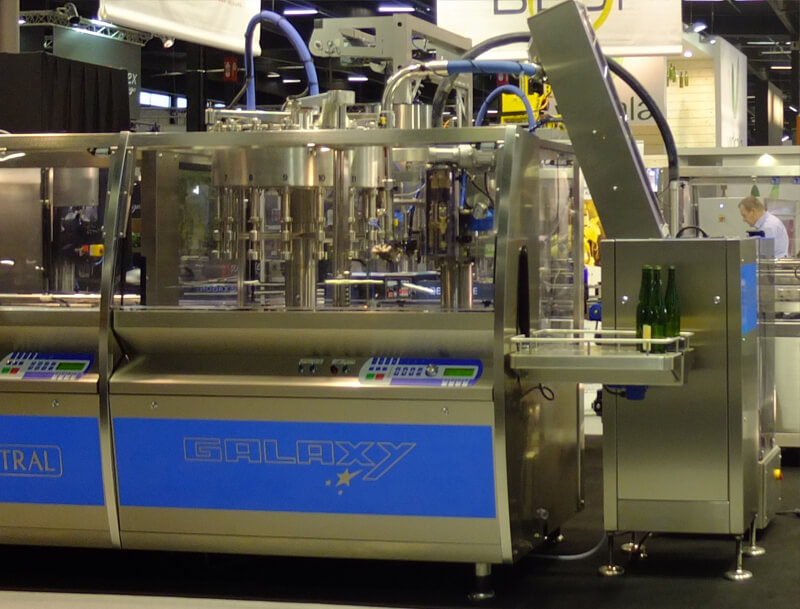

New testing was carried out in collaboration with AGROSCOPE, the oenological research institute in Changins (Switzerland), to compare the effects of filling valves assisted by gentle vacuum and those by simple gravity during filling.

Conditions: Run rate = 1,000 bottles/hour; Machine = GALAXY 2000; Bottles = Bordeaux 75cl screw cap; Wine: Chasselas with 1.6 g/l of CO2; Inerting: Duration of nitrogen injection = 1s48 Nitrogen injection once the nozzle is in the high position and injection shuts off prior to leaving the bottle.

In both cases whether using filling valves assisted by gentle vacuum or not, inerting for empty bottles by entry nozzles reduces the oxygen concentration by over 60%.

In addition, testing at a higher rate (1,830 bottles/hour) has shown a reduction in the concentration rate, namely in the case of the Gravite Simple filling valve with inerting, an average dissolved oxygen concentration of 0.42 mg/l.

In conclusion, simple gravity valves with inerting by entry nozzles are the best solution for wines sensitive to oxidation.

Note that we also offer upgrades for filling valves to adapt to different products such as hot-bottled juice, beer and wine products that you may want to bottle using the turbo model.

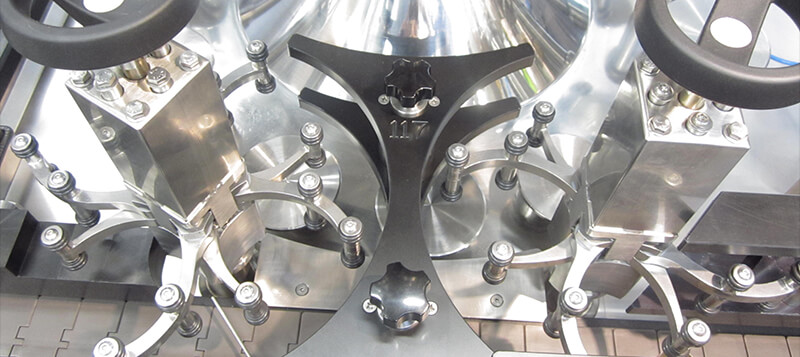

Automatic multi-formats grippers

COSTRAL now offers the multi-format star to handle cylindrical bottles with diameters of 62mm to 107mm.

The advantages:

- A single adjustable selection screw

- Automated synchronised multi-format stars

- At last, equipment available for small production run rates (3,000 bottles/hour, 16 nozzles): a world exclusive !

- Grippers that provide incomparable support for bottles, especially in the sequential movements of the star on the corking machine.

(not to be confused with adjustable stars from our competitors, for whom counter-stars are standard)

New corking machine for Vinolok® glass stoppers

COSTRAL is privileged to partner Vinolok Preciosa®.

We offer highly effective glass stopper corking solutions, covering all shapes and designs.

As a result, we provide solutions capable of integrating a Vinolok® capping kit into an existing machine, as well as independent and automated solutions that can be integrated into an existing bottling line, by conveyor system, to achieve a run rate of up to 4,000 bottles/hour.

COSTRAL has been handling "traditional" Vinolok® bottling for several years, which is now known as "Low Top". But we have adapted to Vinolok® range developments, and we can handle both "Low Top" and "High Top" caps (the height of the glass stopper changes).

And just for once, COSTRAL adapts to find clever solutions enabling interchangeability between two stoppers in just a few simple manoeuvres!

COSTRAL is by your side every step of the way

Your project from start to finish

Are you looking for a new bottling line, need additional equipment or an upgrade?

Whatever your project, COSTRAL is here to help you make it happen!

Directing elevators for corks

Directing elevators for traditional corks

The EB3000 directing elevator has a capacity for 5,000 corks, propelling corks in a feed pipe to the corker downpipe or into a hopper positioned on the machine.

Directing elevators for screw caps

The EC4000 directing elevator has a large loading capacity. It is more accessible, quieter and more flexible in terms of installation, thanks to the standard (or customised) feeding pipe which allows the elevator to be positioned in the most suitable place.

Directing elevator equipment:

- Storage for caps in bulk

- Cap selection

- Cap orientation

- Routing

- Positioning caps on bottles

- Stamping caps

- Inerting into the bottle neck

- Inerting for caps

Different options allow you to choose only elevating caps in bulk or, in just a few minutes, to transform the directing elevator into a multiformat elevator to feed a hopper.

Its new dispensing head with position control and high and low level detection, is suitable for STELVIN, STELVIN LUX, 30H60 and/or 31.5H60 screw caps.

Elevator for HELIX corks

COSTRAL work in collaboration with AMORIM, the creator of HELIX corks.

The HELIX directing elevator was created from this collaboration which mechanically directs HELIX corks, which can be completed with more advanced orientation options.