Based on the siphon principle, the FIAMAT 2000 filler ensures bottled products are handled with the greatest respect,

while achieving a run rate of 2,000 bottles/hour thanks to its 14 nozzles.

An injection of neutral gas ensures millimetre level equalising in the bottle neck prior to corking.

The head interchangeability makes it possible to quickly switch between traditional corks, synthetic corks, crown caps and screw caps.

Efficient, mobile and compact bottling

This automatic bottling unit is made entirely of stainless steel and mounted on wheels.

The FIAMAT consists of a siphon filler with 14 nozzles which is highly efficient and offers moderate filling with no froth. The filler can be easily detached without the need of a tool.

Supply is fed from above and adjusted by a mechanical and electrical float using gravity filling, or an external pump.

The bottles are then transferred slowly and evenly to the eight-branch star of the corker.

The bottle has a short injection of neutral gas, prior to corking, to remove any air from the neck and adjust the level of each bottle with millimetric accuracy.

The corker consists of a stainless-steel compressor with 4 corking jaws which is easy to detach.

A high-performance vacuum pump allows air vacuum corking. The cork hopper located above the corker has a perforated stainless-steel sheet ensuring any dust is removed from the corks.

For any change in bottle format, the height of the filler and corker can be adjusted simultaneously.

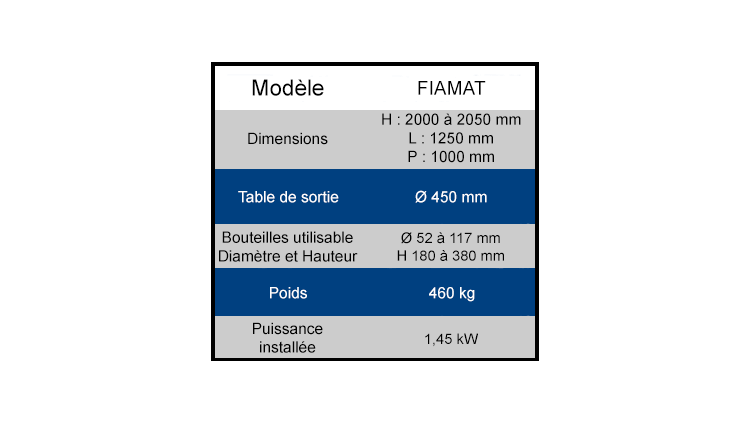

At the outlet, the bottles arrive on a rotating accumulation table with a diameter of 450mm. The speed variation by frequency inverter enables the run rate to be accurately set and perfectly synchronised with all the mechanisms.

The machine is equipped for a type of cylindrical bottle and safety protection that meets all the regulated standards in force. The maximum run rate is 2000 bottles/hour depending on the bottles fed by the operator.

The major advantages of the FIAMAT Filler Corker

The FIAMAT 2000 bottling unit is a compact, mobile machine, with over 4000 systems have been sold worldwide!

Why is it so successful?

- It can be totally dismantled for optimum cleaning, without the need for any tools

- A stainless-steel corker with 4 corking jaws and hopper on the top of the column

- Interchangeable cap heads (crown caps, head caps, screw caps, pressure caps, etc.)

- A rotating table at the outlet and connection to a labelling machine

COSTRAL Services: By your side

COSTRAL Services, supports you throughout your machine installations and training programmes.

We are by your side from the start to the finish of your investment project and are here to answer your all your technical, operational, training and maintenance queries.

Every machine is supplied with a general maintenance guide, and there is a dedicated After-Sales support hotline to deal with any queries relating to operating the machines manufactured in our Riquewihr workshops (in Alsace).

Contact us directly on +33 (0)3 89 47 89 45.