EC4000 pressure switch option

05 févr. 2020 15:00

This isn't new, but here's a little reminder about a lesser known option…

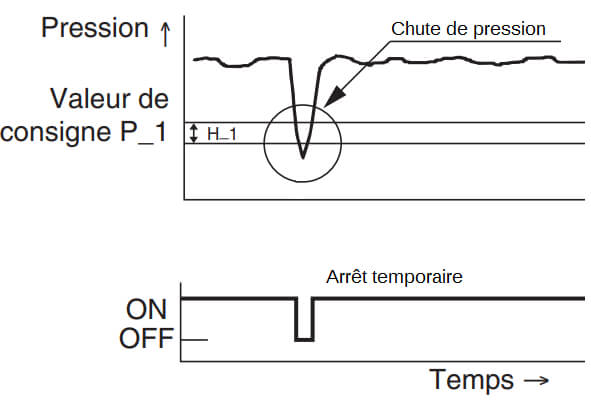

The "EC4000 adjustable pressure switch" option is able to shut down the machine when the pressure drops in the customer's air network. If there is not enough pressurised air, this can cause several cap defects when re-positioned or when shipped either in routing or through bad handling. The machine is stopped and then restarted automatically when the pressure is reached again.

These cases can happen when the compressor has several uses: For example, when another machine draws air at the same time as the bottling process, so at the slightest pressure drop the machine stops instead of continuing to run with badly loaded caps, and then restart.

The "EC4000 adjustable pressure switch" option is able to shut down the machine when the pressure drops in the customer's air network. If there is not enough pressurised air, this can cause several cap defects when re-positioned or when shipped either in routing or through bad handling. The machine is stopped and then restarted automatically when the pressure is reached again.

These cases can happen when the compressor has several uses: For example, when another machine draws air at the same time as the bottling process, so at the slightest pressure drop the machine stops instead of continuing to run with badly loaded caps, and then restart.